When busy mine operations intersect the local community

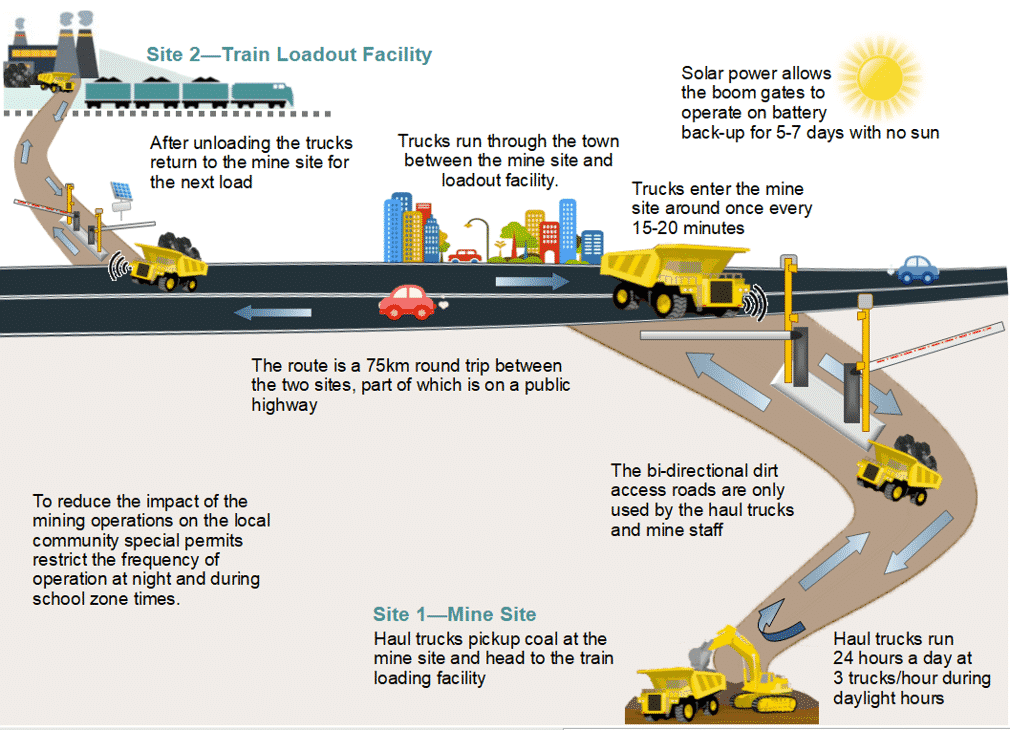

Since commencing operations in 2018 this central Queensland coal mine has been gearing up production and mining operations, now moving coal 24 hours a day with as many as three trucks per hour doing a round trip between the mine and the train loadout facility.

Impact of mine traffic on the township

The 75km round trip involves the haul trucks collecting coal at the mine site, travelling along the dirt access road, joining the main highway, passing through the local township, driving on to the rail loading facility then returning empty via the same route to the mine for the next load.

During peak times heavy-duty trucks leave and enter the public highway as often as every 15-20 minutes making the management of site access a high safety and security priority.

Secure Coast Solutions customised access control system has it covered

Secure Coast Solutions designed an access control system with two key objectives in mind:

- to maximise the safety of the general public, and

- to maintain the efficiency of mining operations.

Considerations for protecting the public

- The bi-directional dirt road that enters the mine site is restricted for use by haul trucks and mine employees. Preventing unauthorised people driving down the mine access road is a priority.

- The mine operators had obtained special permits allowing passage via the highway and through school zones. As the trucks run 24 hours a day, to minimise the impact on the local community, restrictions on the frequency of operations are in place depending on the time of day.

Considerations for maximising haul road traffic efficiency

- If the trucks had to stop each time they enter and exit the mine sites this would have a significant impact on haulage efficiency – increasing travel time, fuel usage as well as wear and tear on the vehicles.

- For the haul trucks to be able to access mine areas without stopping they had to be able to open the boom gates automatically before approaching the control point and automatically close behind them.

- Being dirt roads meant safety loop detectors weren’t suitable and if the road became muddy in the rain PE beams couldn’t be used either.

- In addition to the haul trucks, access was required for maintenance and other mine personnel.

- The location of the boom gates at the entrance to the loadout facility meant power was unavailable.

- For safety and vehicle management mine operators wanted to be able to monitor the location of all trucks along the haulage route.

Efficient Practical Solution in Action

- Boom Gates were installed to prevent unauthorised vehicles from entering mine access roads.

- To allow the haul trucks to pass unhindered through the boom gates they were fitted with long-range RFID tags. When a truck is within 10-15 meters of the boom gate, long-range readers mounted on card reader stands, detect the tags on the bull bar of the haul truck and opens the boom gate.

- Radar safety devices hold the boom gate open as the trucks pass when the radar is clear the boom gate automatically lowers a few seconds later.

- Rotech’s dual height card reader stands allow entry and exit for light and large vehicles not fitted with tags.

- If a truck doesn’t reach its destination within an hour after leaving the mine site the boom gate control system sends an alarm to the control centre. The mine control centre monitors the location of each truck and other traffic. Communications are achieved using 4G routers providing internet access over the mobile phone network.

- Accommodating for varying traffic flows depending on the time of day and for weekends, the Bionik AG automatic boom gate’s multi-function digital controller made set up and programming of the access control system easy.

- Six 120W solar panels were installed to provide power for the entire system. Adding 720amp/hours of battery storage means the solar panels can provide enough power for 4-5 days allowing for overcast weather.

- LED strip lighting on the boom gate arms and illuminated card reader posts provide increased visibility and safety during night works.

Why the Bionik AG Boom Gate was the best choice for the job

“This is a busy, intensive use situation requiring high levels of safety and reliable operation. The Bionik AG boom gates are low in maintenance, fast to activate and are robust and reliable.

LED lights illuminate the boom arms and the electronics are inside a well sealed enclosure protecting the components from coal dust.

All equipment chosen is 100% duty cycle and high temperature rated so it can be used as often as needed. The Bionik AG Automatic Boom Gate featured everything needed to do the job.”

Stuart Bryant – Secure Coast Solutions

For more information about this or other safety and security combinations for your site call Alan Roberts on 07 3250 1123 or email info@rotech.com.au